In the manufacturing world, efficiency and precision are critical. One of the techniques that stands out in terms of improving production rates while maintaining high-quality output is the use of 3 Station Mold systems. This innovative process is widely adopted in industries requiring complex mold manufacturing, offering enhanced productivity by integrating three stations into a single molding cycle. In this article, we’ll explore the key aspects of the 3 Station Mold system, its applications, and how it aligns with broader tooling techniques such as mold design, multi-station tooling, and the differences between “mold” and “mould.”

In the manufacturing world, efficiency and precision are critical. One of the techniques that stands out in terms of improving production rates while maintaining high-quality output is the use of 3 Station Mold systems. This innovative process is widely adopted in industries requiring complex mold manufacturing, offering enhanced productivity by integrating three stations into a single molding cycle. In this article, we’ll explore the key aspects of the 3 Station Mold system, its applications, and how it aligns with broader tooling techniques such as mold design, multi-station tooling, and the differences between “mold” and “mould.”

What is a 3 Station Mold?

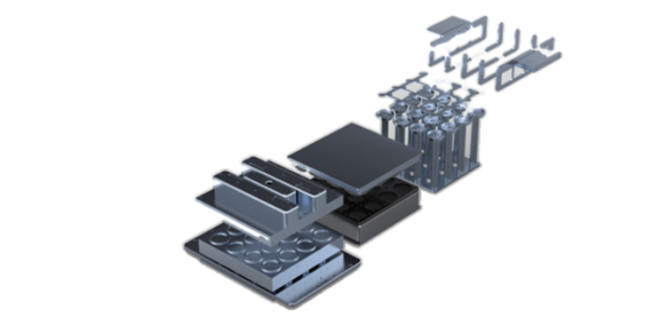

A 3 Station Mold system refers to a type of molding setup where three distinct stages of production occur within one machine. Each stage is dedicated to a different part of the manufacturing process. Typically, the first station injects raw material into the mold, the second station cools or forms the material, and the third station finishes the product by removing the molded part or performing other post-processing tasks.

This multi-station approach increases efficiency by allowing three steps to happen simultaneously. While one station is cooling, another is injecting, and the third is finalizing the part. This cycle reduces the overall production time and boosts output without sacrificing quality.

Mold vs. Mould: The Global Perspective

Before delving deeper into the technicalities of 3 Station Mold processes, it’s essential to address the difference between “mold” and “mould.” While these terms are used interchangeably, they represent the same concept—essentially, a tool used to shape material into a desired form. However, “mold” is the American English spelling, whereas “mould” is the British English equivalent. Depending on the region, one spelling may be preferred over the other, but they both refer to the same tooling process.

In the context of 3 Station Mold systems, whether referred to as mold or mould, the focus remains the same: creating highly precise and efficient tooling systems that optimize the production of molded parts.

The Role of Tooling in 3 Station Mold Systems

Tooling is a crucial part of the 3 Station Mold process, as it involves the design and manufacture of molds used in the production of plastic, metal, or other materials. Tooling for 3 Station Mold setups is particularly complex due to the need for precise alignment and synchronization across the three stations. The mold tooling must accommodate the multi-stage process, ensuring that the material injected at station one seamlessly transitions to the next stations for cooling and finishing.

Tooling design for a 3 Station Mold system typically involves creating multiple cavities in the mold. These cavities are essential for enabling multiple parts to be molded in a single cycle. Additionally, the tooling must account for various factors, such as temperature control, pressure distribution, and material flow to ensure the highest quality final product.

Advantages of 3 Station Mold Systems

1. Increased Production Efficiency

The primary advantage of a 3 Station Mold system is its ability to significantly increase production speed. By integrating three stations into one machine, manufacturers can reduce idle time and streamline the entire molding process. Instead of waiting for each step to finish before moving on to the next, all three stages occur simultaneously.

2. Cost-Effective Manufacturing

By improving the efficiency of the molding process, 3 Station Mold systems help reduce operational costs. The quicker production cycle means that manufacturers can produce more parts in a shorter amount of time, lowering labor costs and increasing throughput. Additionally, this system minimizes material waste, further cutting costs.

3. Consistency and Quality Control

With a 3 Station Mold setup, manufacturers can ensure that each part undergoes a uniform production process. The tooling and mold are designed to maintain strict tolerances, and the automated nature of the system reduces the likelihood of human error. This level of precision is critical in industries such as automotive, aerospace, and consumer goods, where consistency in product quality is paramount.

4. Versatility in Applications

3 Station Mold systems are versatile and can be applied across various industries. Whether it’s plastic injection molding, metal casting, or rubber part production, these systems offer the flexibility needed for complex manufacturing environments. The mold tooling can be customized for specific materials, shapes, and sizes, making the process adaptable to different manufacturing requirements.

Challenges and Considerations in 3 Station Mold Systems

While 3 Station Mold systems offer numerous advantages, there are also challenges that manufacturers must consider. Tooling costs, for example, can be high due to the complexity of the mold design. The precision required to ensure that all three stations work in harmony demands highly skilled engineers and toolmakers.

Another consideration is the maintenance of the mold and tooling. Regular upkeep is essential to avoid defects in the final product. This includes monitoring wear and tear on the mold, ensuring the cooling systems are functioning properly, and recalibrating the machinery as needed.

The 3 Station Mold system represents a significant advancement in the field of manufacturing, offering unparalleled efficiency and precision. Whether in plastics, metals, or other materials, this multi-stage process helps businesses streamline production and reduce costs while maintaining high product quality. By utilizing the right tooling, companies can take full advantage of this technology to stay competitive in fast-paced industries.

Understanding the nuances of mold or mould terminology, the importance of tooling, and the complexities of the 3 Station Mold system is essential for businesses looking to optimize their production capabilities. As technology continues to advance, multi-station mold systems like this will likely play an even more significant role in the future of manufacturing.

Usalia

Usalia